Our process

Beverly Albrets and her team use a number of methods to create their glass artworks. The following illustrates the process of creating a blown glass piece.

The first step we use to blow a piece of glass is called gathering. Here Beverly is collecting glass from the furnace onto the metal pole. The glass furnace is extremely hot, operating at 2,000 plus degrees

Here we see excess molten glass drips off the blowpipe.

Beverly bocking glass to shape it.

Beverley selecting glass to be applied.

During the marver stage, the glass is rolled onto a steel table to gain an on-center cylinder. In this particular photo, the hot-glass is being rolled in materials to add color to the piece that is being created.

Here the hot glass is put back into what is called a glory hole. This is used to remelt the glass to the proper temperature.

More color being applied by Mitch.

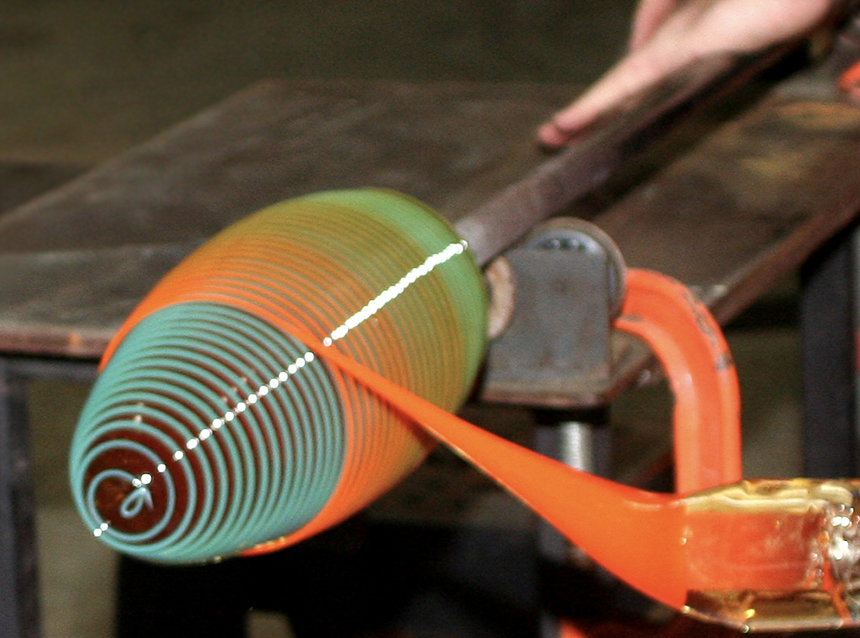

Bill and Mitch threading a piece with hot glass.

The piece after threading is applied.

Beverly shaping the piece.

Beverly blows into the pipe to expand the glass as the team shapes and cools the glass.

Beverly applies lip thread to the glass opening.

Beverly opens the piece with pipe jacks.

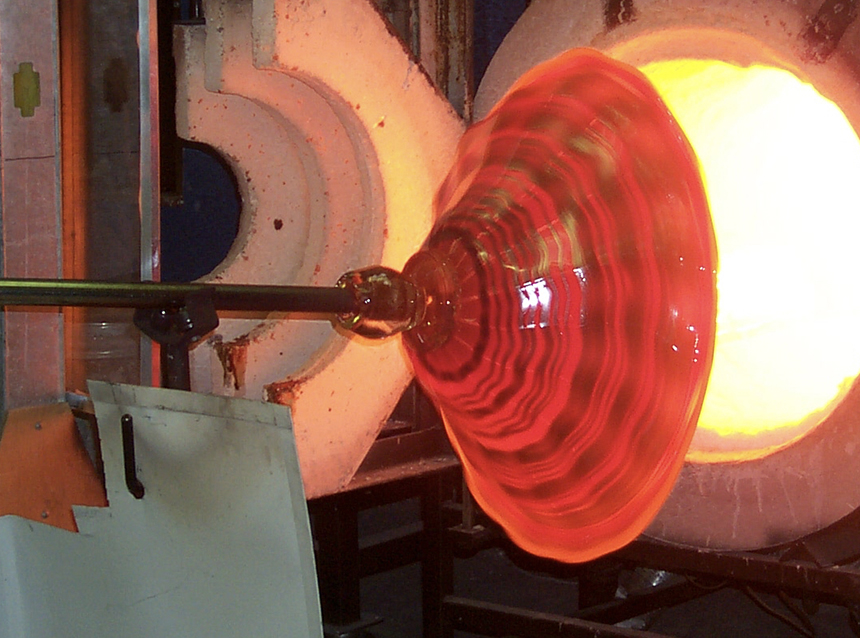

Beverly spinning out a piece to make a large wall form.

Beverly spinning side view.

Mitch takes the piece from Beverly to remove the yoke.

The piece achieves its flared shape and is ready to be knocked off the punty.

A protective suit is worn to put the final piece in the annealer for slow cooking. If the glass is cooled too quickly, it will become unstable and break.

Beverly dancing with a guest to celebrate a good night of glass blowing.

A group of guests watch as Beverly blow glass on a Friday evening.